Asphalt Paving Solutions

Asphalt pavements provide cost-effective and durable surfaces for roads, parking lots, and commercial surfaces while remaining eco-friendly and easily recyclable. Find the best Asphalt Paving in Greensboro.

Topcon offers intelligent compaction solutions to ensure accurate pavement construction. Sitelink3D v2 allows you to keep an eye on pass count, location, and temperature data for both individual compactors or fleets working together.

Longevity

Asphalt pavement is known for its long lifespan, reducing costs associated with maintenance for property owners. It’s durable, easily repairable, and resists cracks and other damages for extended periods. Plus, it adds visual appeal by boasting its distinctive black hue – something no other material can match!

However, the lifespan of asphalt paving is dependent on several factors. One is climate, which can accelerate its degradation faster than other materials – for instance, harsh heat can make asphalt lose strength more rapidly, while cold climates may damage it by freezing and thawing repeatedly.

Traffic volume also plays a factor in wearing down an asphalt surface quickly. Heavy vehicle use, huge trucks or buses, can hasten its degradation.

Proper maintenance and regular resurfacing of asphalt pavements can extend their lives substantially. This includes making sure soil conditions are strong beneath, applying an adequate thickness of asphalt, and making sure it drains well. Sealcoating applications provide further protection from weathering and environmental conditions; filling small cracks as soon as they appear is also crucial; left untreated, they could allow destructive water or chemicals into the surface and cause irreparable damage to the pavement.

Durability

Asphalt is an exceptionally durable material that can withstand both heavy traffic and extreme weather conditions and is easily maintained or repaired through various paving solutions like crack filling and seal coating. Furthermore, asphalt offers more affordable options than concrete for driveways and parking lots alike.

Asphalt’s durability can be further increased through the addition of specialty aggregates and additives, such as fibers, tar emulsions, and recycled rubber tires. Furthermore, asphalt offers more environmental sustainability compared to wood or cement due to its recycled content, reducing waste and pollution; its flexibility also allows it to adapt quickly to changes in load or traffic patterns.

High-quality asphalt pavements can withstand years of traffic without needing constant repair or replacement, reducing repair or replacement needs over time. Durability depends on several factors, including the quality of paving material used during the installation process and regular inspections to extend its life expectancy.

Asphalt is a mixture of aggregates and bitumen used for building roads, parking areas, railway tracks, ports, airport runways, and bicycle lanes. Aggregates used can include crushed rock, sand gravel, or recycled materials like concrete shingles. Most commonly, petroleum-based bitumen is used as the adhesive between aggregates; however, there are currently bio-based binder systems under development that could provide alternatives.

Flexibility

Asphalt paving is highly adaptable and can easily take the form of other materials, from brick and tiled streets to stained or colored surfaces that meet a particular aesthetic. Being weather resistant, repairs for asphalt pavement require less frequent replacement. Plus, its sound absorption properties help lower traffic noise!

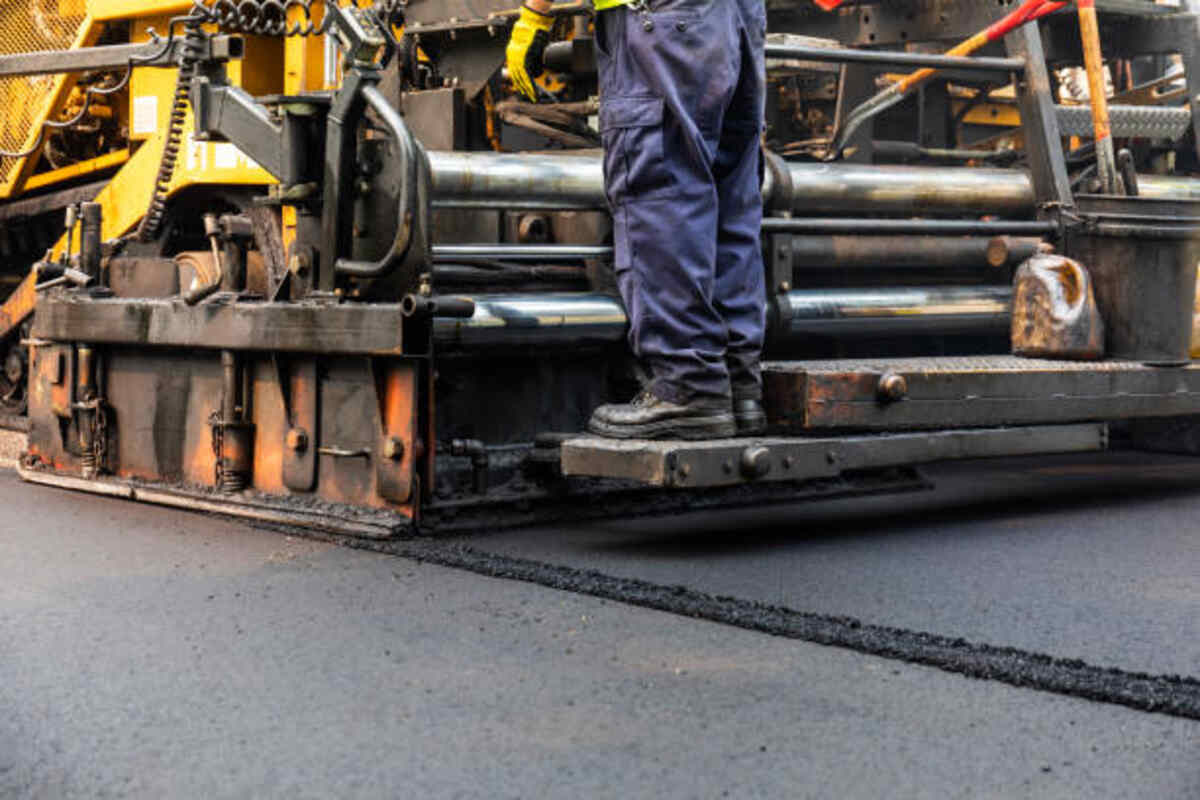

Before asphalt can be laid on any road, it must be graded. Grading involves shaping the base and slope to create a solid load-bearing surface. Once graded, contractors begin installing sub-base material, which is typically composed of aggregate materials like crushed stone and gravel. Following that comes a binder course designed to distribute vehicle weight across pavement surfaces while avoiding rutting evenly. Binder courses must feature high stiffness resistance but still absorb vibration from vehicle wheels for best results.

Finally, the surface course must be installed and rolled – this process compacts and smoothes the asphalt so that it is thick enough and strong enough to support cars. After moving is complete, it must cure and be excellent for several months (depending on weather conditions), during which period traffic must remain off of it while workers add striping marking lanes and crosswalks.

Safety

Asphalt paving solutions must take all measures necessary to protect those working with it, from protecting eyes and skin to providing appropriate equipment and adhering to safety precautions. A worker must remain alert during paving for potential tripping hazards like catch basins, manhole covers, and power lines; these should be clearly marked and kept free of obstruction in order to prevent injury. Workers should also remain wary of heavy machinery. Reputable contractors prohibit sources of ignition on paving sites, such as open flames and electricity sources, to reduce risks as much as possible.

As asphalt mixes can vary significantly in their composition and toxicity levels, workers should receive detailed information on each blend they handle through Safety Data Sheets (SDS) provided to them. These documents include critical details like flashpoint, boiling point, acute/chronic effects, chemical ingredients used, recommended PPE as well as fire and emergency cleanup procedures.

Asphalt should never be mixed in an open kettle as this can release harmful fumes, leading to lung issues and skin irritation, eye damage from direct contact, and even eye injury from direct inhalation of liquid mixture. Workers must always wear appropriate personal protective equipment, such as face shields and respirators, to help avoid breathing in toxic fumes and protect their skin from burns.